HLKA Hydraulic Link Clamp - Hydraulic cylinder

Hydraulic Leverage Clamp - double acting :

- very compact series with low flange design

- suitable especially for compact and light fixtures with high clamping forces.

- double acting type

- High clamping forces 2,1kN up to 31kN

- Clamping force depends on the clamp arm length and hydraulic pressure

- complete with clamping arm and screw

- Use flow control valve for meter-in control.

- Min. operating pressure : 10bar

- Max. operating pressure : 70bar

- Range of Temperature : -10 ~ +70°C

- various sizes and types

- with optional air sensing !

- similar to HLA, Clamptek CLKA, CLU etc.

➝ CAD-files and prices on Request !

Ordering Indication:

HLKA - 32 C M L

Series – Size – Port Type - Air Sensing - Lever direction

| ① | SERIES | HLKA | |

| ② | Body size/ Cylinder inside diameter [mm] |

036: ΦI36 040: ΦI40 048: ΦI48 055: ΦI55 065: ΦI65 075: ΦI75 090: ΦI90 105: ΦI05 |

|

| ③ | Port Type | Blank: Standard Line type (with PT Thread Port) G: Manifold type (with G Thread Plug) C: Manifold with flow type (with G Thread Plug) |

|

| ④ | Air sensing | Blank: Standard (without sensing) D: Double End Rod option M: Air Sensing Manifold option N: Air Sensing Piping Option |

|

| ⑤ | Lever direction | Blank: Standard front side R: Right side L: Left side |

| Model | Clamping force at 70 bar | Clamping stroke | Total stroke | Oil capacity Clamp | Oil capacity Unclamp | eff. piston area clamp | eff. piston area unclamp | CAD |

|---|---|---|---|---|---|---|---|---|

| [kN] | [mm] | [mm] | [cm³] | [cm³] | [cm²] | [cm²] | ||

| HLKA-036 | 2,07 | 16 | 18,5 | 7,03 | 5,57 | 3,80 | 3,01 | |

| HLKA-040 | 2,74 | 17,5 | 20,5 | 10,07 | 7,75 | 4,91 | 3,78 | |

| HLKA-048 | 4,52 | 20,5 | 23,5 | 18,89 | 15,28 | 8,04 | 6,50 | |

| HLKA-055 | 6,49 | 23 | 26 | 32,66 | 27,43 | 12,56 | 10,55 | |

| HLKA-065 | 10,73 | 26,5 | 29,5 | 57,91 | 48,65 | 19,63 | 16,49 | |

| HLKA-075 | 17,79 | 32 | 35 | 109,06 | 95,76 | 31,16 | 27,36 | |

| HLKA-090 | 21,35 | 38 | 41 | 141,37 | 132,55 | 34,48 | 32,33 | |

| HLKA-105 | 30,94 | 46 | 49 | 246,18 | 199,04 | 50,24 | 40,62 |

| MODEL | A | J2 | J1 | I | B | F | C | Z | K | L | C1 | C2 | N | M | Q | R | S | W | G3 | Y | C3 | G2 | D | D1 | G1 | α | E | G4 | øU | PORT WITH Line Type | O-Ring HOLE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HLKA-036 | 78,5 | 49 | 40 | 36 | 48 | 23 | 10 | 20 | 31,4 | 66 | 12,5 | 6 | 23,5 | 16 | 7,5 | 4,5 | 15,5 | 30 | 20 | 11 | 19 | 14,5 | 5 | 5 | 37 | 19,6 | 17 | 19 | ø10 | 2-PT1/8 | P5 |

| HLKA-040 | 87,5 | 54 | 45 | 40 | 54 | 29 | 12 | 22,5 | 34 | 72 | 14 | 8 | 26 | 18 | 9 | 5,5 | 15 | 30,5 | 22 | 13 | 21 | 16 | 6 | 6 | 40 | 20,2 | 17,5 | 20,5 | ø12 | 2-PT1/8 | P5 |

| HLKA-048 | 99,0 | 61 | 51 | 48 | 60 | 32 | 12 | 25,5 | 40 | 81 | 16 | 8 | 30 | 22 | 9 | 5,5 | 16 | 34,5 | 26 | 13 | 24 | 18,5 | 6 | 6 | 47 | 18,9 | 21,5 | 23,5 | ø14 | 2-PT1/8 | P5 |

| HLKA-055 | 110,5 | 69 | 60 | 55 | 65 | 37 | 16 | 30 | 47 | 88 | 20 | 12 | 33,5 | 24 | 11 | 6,8 | 13,5 | 35,5 | 30 | 16 | 28 | 21 | 6 | 8 | 55 | 19,3 | 25 | 29 | ø16 | 2-PT1/8 | P5 |

| HLKA-065 | 127,5 | 81 | 70 | 65 | 73,5 | 43,5 | 19 | 35 | 55 | 106 | 25 | 17 | 39,5 | 30 | 11 | 6,8 | 16 | 39 | 35,5 | 19 | 37 | 24,5 | 8 | 10 | 61,5 | 20 | 26,5 | 32 | ø20 | 2-PT1/4 | P7 |

| HLKA-075 | 151 | 94,5 | 85 | 75 | 84 | 47 | 22 | 42,5 | 63 | 116 | 32 | 24 | 45 | 32 | 14 | 9 | 17,5 | 48 | 43,5 | 25 | 40 | 30 | 10 | 12 | 72,5 | 21,4 | 30 | 37,5 | ø22 | 2-PT1/4 | P7 |

| HLKA-090 | 180 | 109,5 | 100 | 90 | 101 | 61 | 25 | 50 | 75 | 136 | 38 | 30 | 52,5 | 37 | 17,5 | 11 | 17 | 52,5 | 52,5 | 28 | 49 | 36 | 12 | 15 | 82,5 | 22,4 | 32,5 | 41,5 | ø28 | 2-PT3/8 | P7 |

| HLKA-105 | 209 | 127 | 120 | 105 | 115 | 65 | 32 | 60 | 88 | 152 | 45 | 37 | 60 | 45 | 20 | 14 | 23 | 64 | 64 | 32 | 64 | 44 | 15 | 18 | 100 | 23,1 | 40 | 51 | ø35 | 2-PT3/8 | P7 |

| Model | Clamping force at 70 bar | Clamping stroke | Total stroke | Oil capacity Clamp | Oil capacity Unclamp | eff. piston area clamp | eff. piston area unclamp |

CAD |

|---|---|---|---|---|---|---|---|---|

| [kN] | [mm] | [mm] | [cm³] | [cm³] | [cm²] | [cm²] | ||

| HLKA-036D | 2,14 | 16,5 | 18,5 | 7,4 | 6,9 | 4,02 | 3,55 | |

| HLKA-040D | 2,28 | 17,5 | 20,5 | 8,6 | 8,6 | 4,18 | 4,18 | |

| HLKA-048D | 3,04 | 20,5 | 23,5 | 13,0 | 13,0 | 5,53 | 5,53 | |

| HLKA-055D | 4,09 | 23 | 26 | 21,0 | 19,8 | 8,08 | 7,61 | |

| HLKA-065D | 7,71 | 26,5 | 29,5 | 42,4 | 37,7 | 14,4 | 12,8 | |

| HLKA-075D | 11,87 | 32 | 35 | 74,2 | 69,8 | 21,2 | 19,94 | |

| HLKA-090D | 20,52 | 38 | 41 | 138,5 | 123,7 | 33,8 | 30,2 | |

| HLKA-105D | 28,80 | 46 | 49 | 233,8 | 197,8 | 47,7 | 40,35 |

| MODEL | A | J2 | J1 | I | B | F | Z | K | L | G4 | α | N | M | Q | R | S | W | G3 | Y | C3 | G2 | D | D1 | ΦDA | DB | DC | DD (NominalxDepth) | ΦU | PORT WITH LINE TYPE | O-RING HOLE (C/G TYPE) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HLKA-036D | 89 | 49 | 40 | 36 | 48 | 23 | 20 | 31.4 | 66 | 19 | 19.6 | 23.5 | 16 | 7.5 | 4.5 | 15.5 | 30 | 20 | 11 | 19 | 14.5 | 5 | 5 | 8 | 10.5 | 6 | M4×10 | Φ10 | 2-PT1/8 | P5 |

| HLKA-040D | 100.5 | 54 | 45 | 40 | 54 | 29 | 22.5 | 34 | 72 | 20.5 | 20.2 | 26 | 18 | 9 | 5.5 | 15 | 30.5 | 22 | 13 | 21 | 16 | 6 | 6 | 12 | 13 | 10 | M6×15 | Φ12 | 2-PT1/8 | P5 |

| HLKA-048D | 112 | 61 | 51 | 48 | 60 | 32 | 25.5 | 40 | 81 | 23.5 | 18.9 | 30 | 22 | 9 | 5.5 | 16 | 34.5 | 26 | 13 | 24 | 18.5 | 6 | 6 | 14 | 13 | 12 | M8×18 | Φ14 | 2-PT1/8 | P5 |

| HLKA-055D | 123.5 | 69 | 60 | 55 | 65 | 37 | 30 | 47 | 88 | 29 | 19.3 | 33.5 | 24 | 11 | 6.8 | 13.5 | 35.5 | 30 | 16 | 28 | 21 | 6 | 8 | 14 | 13 | 12 | M8×18 | Φ16 | 2-PT1/4 | P5 |

| HLKA-065D | 140.5 | 81 | 70 | 65 | 73.5 | 43.5 | 35 | 55 | 106 | 32 | 20 | 39.5 | 30 | 11 | 6.8 | 16 | 39 | 35.5 | 19 | 37 | 24.5 | 8 | 10 | 14 | 13 | 12 | M8×18 | Φ20 | 2-PT1/4 | P7 |

| HLKA-075D | 164 | 94.5 | 85 | 75 | 84 | 47 | 42.5 | 63 | 116 | 37.5 | 21.4 | 45 | 32 | 14 | 9 | 17.5 | 48 | 43.5 | 25 | 40 | 30 | 10 | 12 | 18 | 13 | 16 | M10×21 | Φ22 | 2-PT3/8 | P7 |

| HLKA-090D | 193 | 109.5 | 100 | 90 | 101 | 61 | 50 | 75 | 136 | 41.5 | 22.4 | 52.5 | 37 | 17.5 | 11 | 17 | 52.5 | 52.5 | 28 | 49 | 36 | 12 | 15 | 18 | 13 | 16 | M10×21 | Φ28 | 2-PT3/8 | P7 |

| HLKA-105D | 222 | 127 | 120 | 105 | 115 | 65 | 60 | 88 | 152 | 51 | 23.1 | 60 | 45 | 20 | 14 | 23 | 64 | 64 | 32 | 64 | 44 | 15 | 18 | 18 | 13 | 16 | M10×21 | Φ35 | 2-PT3/8 | P7 |

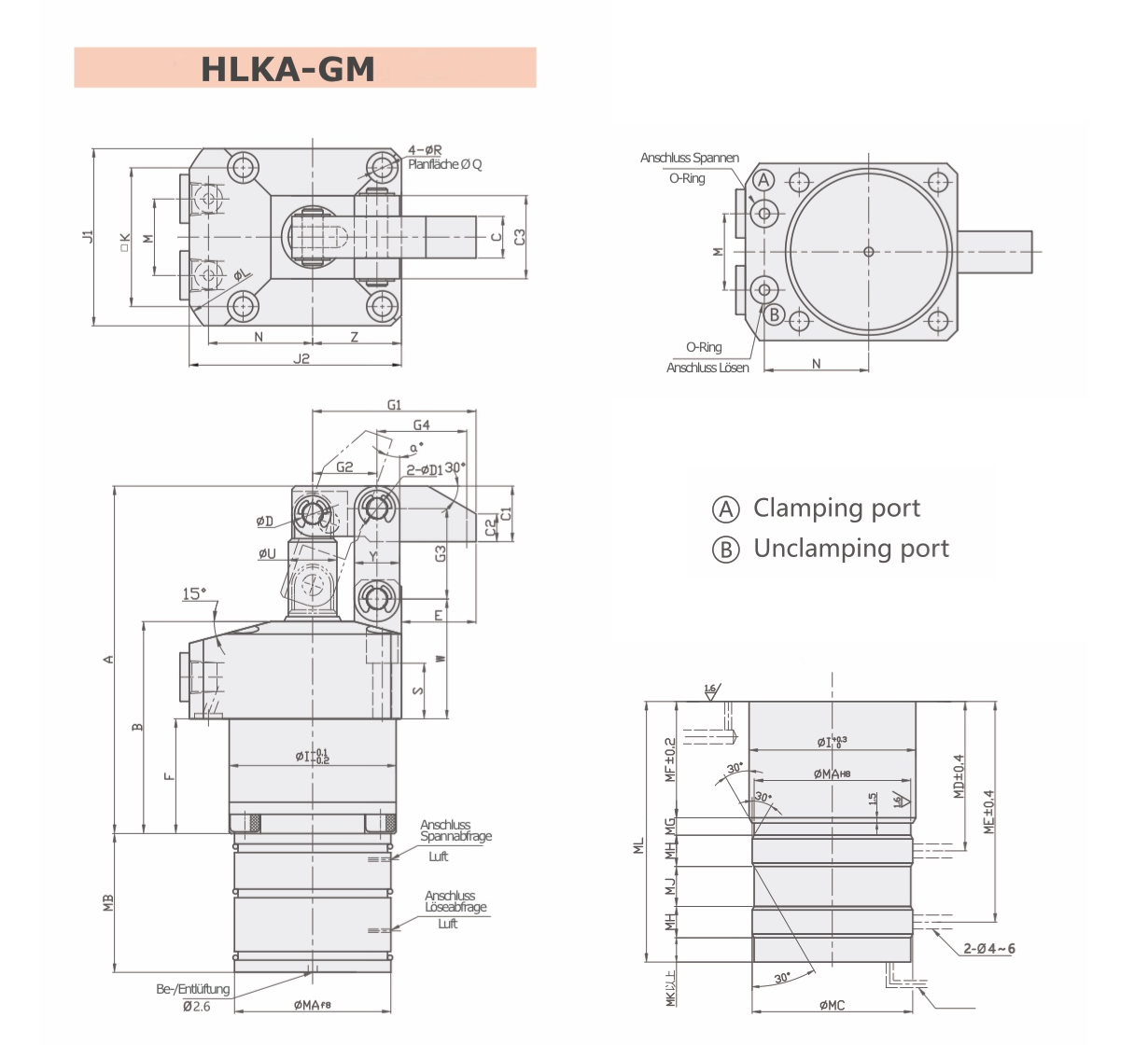

| MODEL | A | J2 | J1 | I | B | F | C | Z | K | L | C1 | C2 | N | M | Q | R | S | W | G3 | Y | C3 | G2 | D | D1 | G1 | α | E | G4 | ΦU | PORT WITH LINE TYPE | O-RING HOLE (C/G TYPE) | MAf8 | MAH8 | MB | MC | MD | ME | MF | MG | MH | MJ | MK | ML |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HLKA-036M | 78.5 | 49 | 40 | 36 | 48 | 23 | 10 | 20 | 31.4 | 66 | 12.5 | 6 | 23.5 | 16 | 7.5 | 4.5 | 15.5 | 30 | 20 | 11 | 19 | 14.5 | 5 | 5 | 37 | 19.6 | 17 | 19 | Φ10 | 2-PT1/8 | P5 | 34.5-0.03/-0.06 | 34.5+0.04/0 | 31 | 35.7 | 32.5 | 45.5 | 23.5 | 4.5 | 9 | 4 | 6 | 56 |

| HLKA-040M | 88.5 | 54 | 45 | 40 | 55 | 30 | 12 | 22.5 | 34 | 72 | 14 | 8 | 26 | 18 | 9 | 5.5 | 15 | 30.5 | 22 | 13 | 21 | 16 | 6 | 6 | 40 | 20.2 | 17.5 | 20.5 | Φ12 | 2-PT1/8 | P5 | 38-0.03/-0.06 | 38+0.04/0 | 36 | 39.2 | 40 | 56.5 | 30.5 | 5 | 9 | 7.5 | 7 | 68 |

| HLKA-048M | 100 | 61 | 51 | 48 | 61 | 33 | 12 | 25.5 | 40 | 81 | 16 | 8 | 30 | 22 | 9 | 5.5 | 16 | 34.5 | 26 | 13 | 24 | 18.5 | 6 | 6 | 47 | 18.9 | 21.5 | 23.5 | Φ14 | 2-PT1/8 | P5 | 45-0.03/-0.06 | 45+0.04/0 | 40 | 46.2 | 43 | 63.5 | 33.5 | 5 | 9 | 11.5 | 7 | 75 |

| HLKA-055M | 114 | 69 | 60 | 55 | 68.5 | 40.5 | 16 | 30 | 47 | 88 | 20 | 12 | 33.5 | 24 | 11 | 6.8 | 13.5 | 35.5 | 30 | 16 | 28 | 21 | 6 | 8 | 55 | 19.3 | 25 | 29 | Φ16 | 2-PT1/4 | P5 | 45-0.03/-0.06 | 45+0.04/0 | 40 | 46.2 | 50.5 | 71 | 41 | 5 | 9 | 11.5 | 7 | 82.5 |

| HLKA-065M | 134.5 | 81 | 70 | 65 | 80.5 | 50.5 | 19 | 35 | 55 | 106 | 25 | 17 | 39.5 | 30 | 11 | 6.8 | 16 | 39 | 35.5 | 19 | 37 | 24.5 | 8 | 10 | 61.5 | 20 | 26.5 | 32 | Φ20 | 2-PT1/4 | P7 | 53-0.03/-0.07 | 53+0.04/0 | 40 | 46.2 | 60.5 | 81 | 51 | 5 | 9 | 11.5 | 7 | 92.5 |

| HLKA-075M | 153 | 94.5 | 85 | 75 | 88 | 49 | 22 | 42.5 | 63 | 116 | 32 | 24 | 45 | 32 | 14 | 9 | 17.5 | 48 | 43.5 | 25 | 40 | 30 | 10 | 12 | 72.5 | 21.4 | 30 | 37.5 | Φ22 | 2-PT3/8 | P7 | 53-0.03/-0.07 | 53+0.04/0 | 59.5 | 54.2 | 61 | 93.5 | 49.5 | 5.5 | 12 | 20.5 | 11 | 110.5 |

| HLKA-090M | 186 | 109.5 | 100 | 90 | 107 | 67 | 25 | 50 | 75 | 136 | 38 | 30 | 52.5 | 37 | 17.5 | 11 | 17 | 52.5 | 52.5 | 28 | 49 | 36 | 12 | 15 | 82.5 | 22.4 | 32.5 | 41.5 | Φ28 | 2-PT3/8 | P7 | 53-0.03/-0.07 | 53+0.04/0 | 59.5 | 54.2 | 79 | 111.5 | 67.5 | 5.5 | 12 | 20.5 | 11 | 128.5 |

| HLKA-105M | 223 | 127 | 120 | 105 | 129 | 79 | 32 | 60 | 88 | 152 | 45 | 37 | 60 | 45 | 20 | 14 | 23 | 64 | 64 | 32 | 64 | 44 | 15 | 18 | 100 | 23.1 | 40 | 51 | Φ35 | 2-PT3/8 | P7 | 53-0.03/-0.07 | 53+0.04/0 | 59.5 | 54.2 | 91 | 123.5 | 79.5 | 5.5 | 12 | 20.5 | 11 | 140.5 |

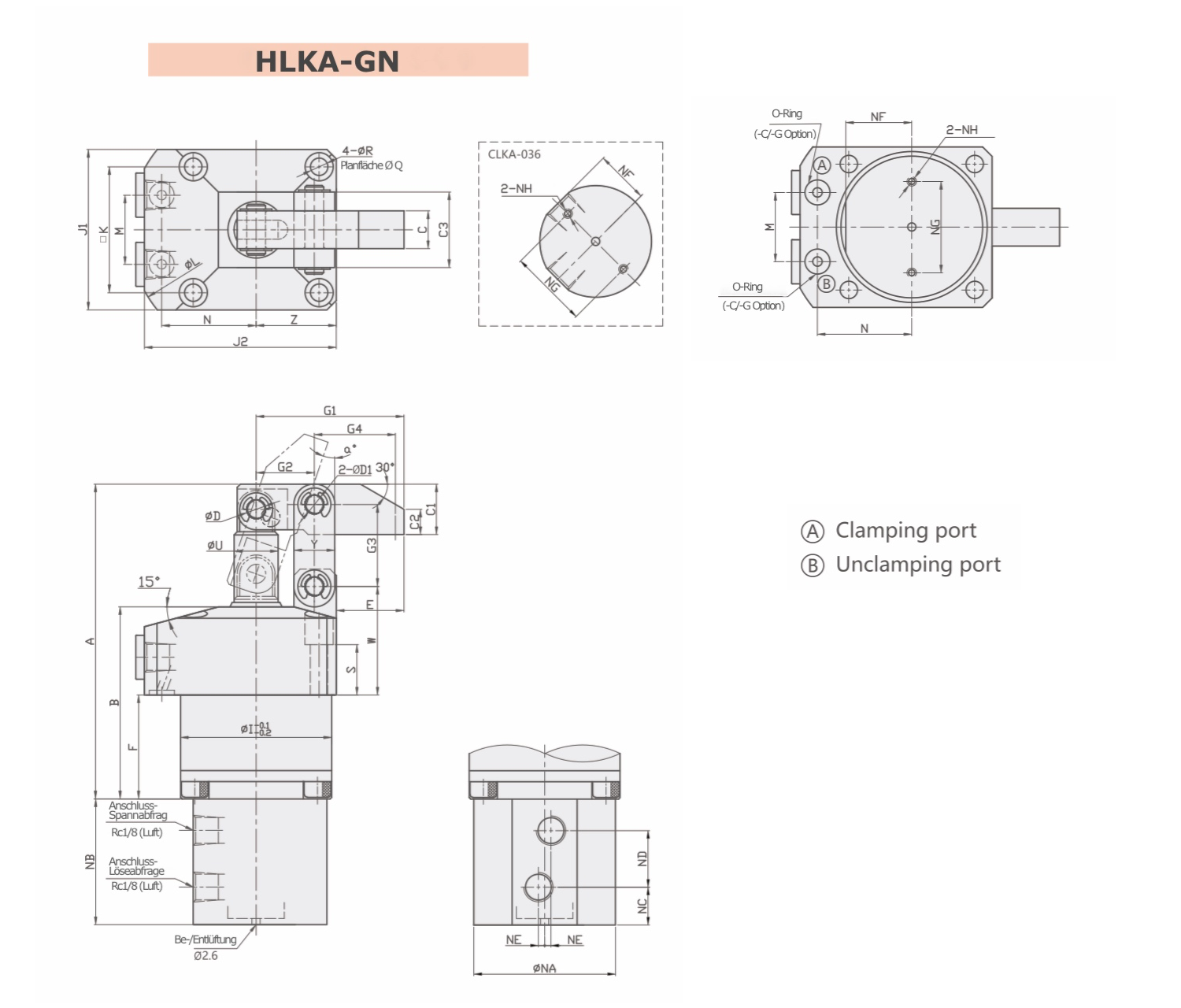

| MODEL | A | J2 | J1 | I | B | F | C | Z | K | L | C1 | C2 | N | M | Q | R | S | W | G3 | Y | C3 | G2 | D | D1 | G1 | α | E | G4 | ΦU | PORT WITH LINE TYPE | O-RING HOLE (C/G TYPE) | ΦNA | NB | NC | ND | NE | NF | NG | NH (NominalxDepth) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HLKA-036N | 78.5 | 49 | 40 | 36 | 48 | 23 | 10 | 20 | 31.4 | 66 | 12.5 | 6 | 23.5 | 16 | 7.5 | 4.5 | 15.5 | 30 | 20 | 11 | 19 | 14.5 | 5 | 5 | 37 | 19.6 | 17 | 19 | Φ10 | 2-PT1/8 | P5 | 35.5 | 31 | 9 | 12.5 | - | 17 | 25 | M3×0.5×6 |

| HLKA-040N | 88.5 | 54 | 45 | 40 | 55 | 30 | 12 | 22.5 | 34 | 72 | 14 | 8 | 26 | 18 | 9 | 5.5 | 15 | 30.5 | 22 | 13 | 21 | 16 | 6 | 6 | 40 | 20.2 | 17.5 | 20.5 | Φ12 | 2-PT1/8 | P5 | 39.5 | 36 | 8.5 | 17.5 | 1 | 18.5 | 29 | M3×0.5×6 |

| HLKA-048N | 100 | 61 | 51 | 48 | 61 | 33 | 12 | 25.5 | 40 | 81 | 16 | 8 | 30 | 22 | 9 | 5.5 | 16 | 34.5 | 26 | 13 | 24 | 18.5 | 6 | 6 | 47 | 18.9 | 21.5 | 23.5 | Φ14 | 2-PT1/8 | P5 | 45 | 40 | 12 | 18 | 2 | 20 | 29 | M3×0.5×6 |

| HLKA-055N | 114 | 69 | 60 | 55 | 68.5 | 40.5 | 16 | 30 | 47 | 88 | 20 | 12 | 33.5 | 24 | 11 | 6.8 | 13.5 | 35.5 | 30 | 16 | 28 | 21 | 6 | 8 | 55 | 19.3 | 25 | 29 | Φ16 | 2-PT1/4 | P5 | 45 | 40 | 12 | 18 | 2 | 20 | 29 | M3×0.5×6 |

| HLKA-065N | 134.5 | 81 | 70 | 65 | 80.5 | 45 | 19 | 35 | 55 | 106 | 25 | 17 | 39.5 | 30 | 11 | 6.8 | 16 | 39 | 35.5 | 19 | 37 | 24.5 | 8 | 10 | 61.5 | 20 | 26.5 | 32 | Φ20 | 2-PT1/4 | P7 | 45 | 40 | 12 | 18 | 2 | 20 | 29 | M3×0.5×6 |

| HLKA-075N | 153 | 94.5 | 85 | 75 | 86 | 49 | 22 | 42.5 | 63 | 116 | 32 | 24 | 45 | 32 | 14 | 9 | 17.5 | 48 | 43.5 | 25 | 40 | 30 | 10 | 12 | 72.5 | 21.4 | 30 | 37.5 | Φ22 | 2-PT3/8 | P7 | 53 | 59.5 | 20 | 29.5 | 3 | 24 | 38 | M4×0.7×7 |

| HLKA-090N | 186 | 109.5 | 100 | 90 | 107 | 67 | 25 | 50 | 75 | 136 | 38 | 30 | 52.5 | 37 | 17.5 | 11 | 17 | 52.5 | 52.5 | 28 | 49 | 36 | 12 | 15 | 82.5 | 22.4 | 32.5 | 41.5 | Φ28 | 2-PT3/8 | P7 | 53 | 59.5 | 20 | 29.5 | 3 | 24 | 38 | M4×0.7×7 |

| HLKA-105N | 223 | 127 | 120 | 105 | 129 | 79 | 32 | 60 | 88 | 152 | 45 | 37 | 60 | 45 | 20 | 14 | 23 | 64 | 64 | 32 | 64 | 44 | 15 | 18 | 100 | 23.1 | 40 | 51 | Φ35 | 2-PT3/8 | P7 | 53 | 59.5 | 20 | 29.5 | 3 | 24 | 38 | M4×0.7×7 |